Air Voids In Asphalt - Technical Note

INTRODUCTION

This Technical Note provides information regarding the recent change to the VicRoads asphalt density reporting for Standard Specification Section 407 Hot Mix Asphalt.

The reporting has been changed to improve clarity of field results, and provide consistent reporting of density across Australia.

The proportion of air voids in a compacted asphalt mix is a critical performance characteristic. Reporting of field (insitu) air voids will enable focus on this important attribute. The VicRoads asphalt specifications are expected to be altered in two stages:

• a requirement to report density and air voids

• (later) a requirement to report only air voids.

INFLUENCE OF AIR VOIDS ON ASPHALT PERFORMANCE

Asphalt consists of four main materials: bitumen, aggregate, fillers (fine particles) and air. Asphalt without sufficient air entrapped in the layer will deform under traffic and result in a rutted and rough surface. Field air voids represent the amount of entrapped air in an asphalt layer that has been placed on-site.

In general terms, the aim of asphalt mix design is to achieve an asphalt mix with the lowest practicable air voids without compromising long term performance. Too many air voids and the asphalt becomes permeable to water and air, which causes reduced service life. Too few air voids and the asphalt becomes rutted and deformed under trafficking.

DESIGN AIR VOIDS

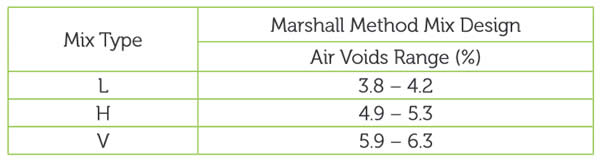

The range of design air void values in laboratory compacted asphalt mixes is included in asphalt mix design standards. Different types of asphalt include different design air voids as shown in Table 1. VicRoads requirements for design air voids are set out in the Code of Practice for Registration of Bituminous Mix Designs (RC 500.01).

Asphalt with high design air voids (eg. Type H) is used for locations with heavy traffic volumes where there is potential for further compaction of the asphalt mix after placing. This type of asphalt is able to withstand heavy traffic loads without deformation, as a result of the high air voids.

Type V asphalt has higher design air voids and is used for heavily trafficked intersections where there is significant potential for further compaction of the asphalt mix after placing. As a result of the higher air voids, Type V asphalt is able to withstand heavy traffic loads and stresses from braking/ accelerating without deformation.

Asphalt with lower design air voids (eg. Type L) is used for locations with light traffic volumes where there is very little further compaction of the asphalt mix after placing. This type of asphalt achieves high levels of durability and fatigue resistance as a result of the lower air voids, and provides long service life. If this type of asphalt was subjected to heavy traffic volumes then significant rutting would be expected.

Table 1 Design Air Voids

Field compaction should attempt to place the asphalt as close as possible to the design air voids so that the asphalt performs as expected. Reduced compaction leads to:

• higher air voids and therefore increased risk of moisture entry

• early oxidation which results in premature ravelling

• a reduction in the structural performance of stiffness and fatigue resistance of the asphalt mix.

VICROADS CURRENT DENSITY TESTING AND REPORTING

VicRoads currently requires compaction testing to report density of the asphalt. The density is reported as the ratio of field density compared to (Marshall) Bulk density.

Density Ratio % = Field density x 100 / Bulk density

Field density results can be determined either by nuclear gauge or by taking cores from the road and determining the result in the laboratory.

Bulk density is the density of the laboratory compacted asphalt mix and includes design air voids. Bulk density is determined during the mix design process and this information is provided as part of asphalt mix registration for VicRoads works.

Air Voids In Asphalt - Technical Note

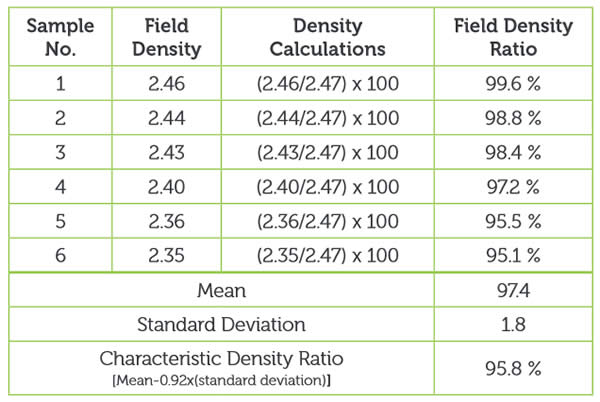

An example of the calculation for characteristic density ratio for asphalt works is shown in Table 2, with bulk density = 2.47 t/m3

Table 2 Calculating Characteristic Density Ratio

The example shows a characteristic density ratio of 95.8%.

VOIDS FREE BULK DENSITY AND DESIGN AIR VOIDS

Voids free bulk density (VFBD) is the density of the asphalt mix without air voids. VFBD is measured in the laboratory on a sample of loose asphalt which is treated to ensure all air has been displaced. VFBD is currently required as part of asphalt mix registration for VicRoads works.

Design air voids is the ratio of the VFBD to the bulk density of the compacted asphalt mix. Design air voids can be checked in laboratory compacted mix using the following equation:

Design air voids = (VFBD – bulk density) x 100 / VFBD

An example extended from Table 2 is: VFBD = 2.60 t/m3

Design air voids = (2.60 – 2.47) x 100 / 2.60 = 5.00%

REPORTING OF FIELD AIR VOIDS

The changes to the VicRoads specification will require field density reporting to include field air voids. The reporting change requires an additional calculation, and does not change the density testing regime or the method of measurement.

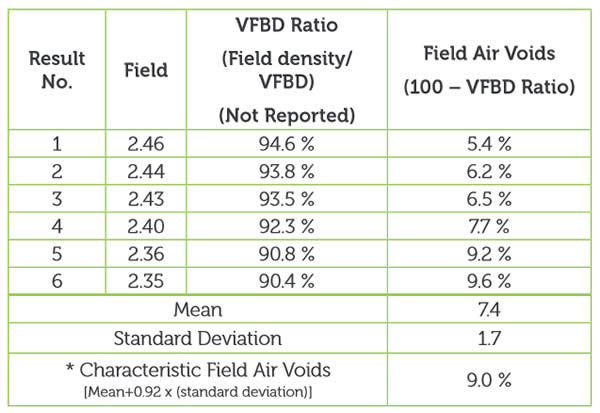

Converting field density to field air voids can be accomplished in various ways. An example of the calculation for characteristic air voids is shown in Table 3 where VFBD = 2.60 t/m3 and bulk density = 2.47 t/m3

Table 3 Calculating Characteristic Field Air Voids

* Note the calculation for the characteristic value has changed.

The 9% Field Air Voids allows us to better assess the condition of the asphalt for service life.

The conversion from CDR to Characteristic Field Air Voids can be calculated using the following:

Characteristic Field Air Voids

= Design Air Voids + (100 - CDR)(bulk density/VFBD)

An example extended from Table 2 is: = 5% + (100-95.8)(2.47/2.60) = 9.0%

SPECIFICATION CHANGES

The revised specification requires both characteristic density ratio and characteristic field air voids to be reported. The regime of testing remains unchanged, and payment continues to be based on density rather than air voids.

REFERENCES

1. VicRoads, RC 500.01 Code of Practice for Registration of Bituminous Mix Designs..

2. VicRoads, Standard Section 407 – Hot Mix Asphalt.

CONTACT OFFICERS

For further information on air voids in asphalt, please contact the following officers:

Andrew Papacostas Ph: 9881 8927

Email : This email address is being protected from spambots. You need JavaScript enabled to view it.

Cassandra Simpson Ph: 9881 8928

Email : This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Consulting believes this publication to be correct at time of printing and does not accept responsibility for any consequences arising from the use of the information herein. Readers should rely on individual judgement and skill to apply information to particular issues.